compression creep test|creep recovery test : exporting Creep is the slow, continuous, inelastic, permanent deformation of materials that increases with time under the action of constant stress. Generally occurs at high temperature, . WEB1 356,2K. Martina Oliver MMXXVI. 13 5 290,2K. Z. 23 years old Italian Instagram star Martina vismara Leaks 🔥link below 👇 Zxerim. 1 170,8K. F. martina smith Squirt Hard over .

{plog:ftitle_list}

Something went wrong. There's an issue and the page could not be loaded. Reload page. 39K Followers, 3,480 Following, 1,989 Posts - See Instagram photos and videos from .

A unidirectional compression creep test has been employed to measure the relaxation modulus of the LFT-D (Matrix: PA6, Fiber: T700SC Toray, Volume Fraction of Fiber: 30%), where a creep function derived by experimental creep test is approximated by a Voigt-viscoelastic model, .Four loading and unloading rates of bulk compressive creep test were 1 N/s, 10 .

The present work developes a novel two-scale method (TSM) which combines a .The creep test, also known as the stress relaxation test, is a destructive way of evaluating a material’s durability and thermal stability. A creep test is one in which the specimen is heated for an extended period and supplied with a constant . Creep is the slow, continuous, inelastic, permanent deformation of materials that increases with time under the action of constant stress. Generally occurs at high temperature, .

Conceptually a creep test is rather simple: Apply a force to a test specimen and measure its dimensional change over time with exposure to a relatively high temperature.Learn about creep testing, a method to measure the deformation of a sample under a constant load and temperature. Find out how to perform creep testing with a material tester and an environmental chamber.

The three types of creep tests were designed to identify the quantitative relations among the compressive and tensile creep strains and the bending creep strain for normal .

Creep tests on plastics in controlled humidity environment from +20°C to 90°C – without humidity control -30°C up to +180°C. Testing plastics and composites according to ISO 899-1 and . Creep tests are often performed by compressive loading to eliminate growth of cavities and their opening and thus creep rate is slower compared to tension. Four loading and unloading rates of bulk compressive creep test were 1 N/s, 10 N/s, 20 N/s, 50 N/s respectively, to evaluate the influence of loading rate on the creep properties of .

The present work developes a novel two-scale method (TSM) which combines a as-short-as-possible uniaxial compression creep test and rapid microindentation creep tests to .

This test method can be used to compare creep potentials of dif . C0512-02|en-US Standard Test Method for Creep of Concrete in Compression Standard C512 Standard Test Method for Creep of Concrete in Compression> new BOS Vol. 04.02 Committee C09 $ 73.00 In stock Significance and Use.ASTM D2990 | Plastics | Tensile, Compressive, and Flexural Creep, Creep Rupture. For Tensile Creep: Measure the sample’s cross-sectional area. Tensile creep and creep-rupture tests use specimens outlined in ASTM D638 or . Maintaining a constant temperature during a creep test is critical due to the possible thermal expansion or shrinkage of the material. . C512-02 “Standard Test Method for Creep of Concrete in Compression” D6992-03(2009) Standard Test Method for Accelerated Tensile Creep and Creep-Rupture of Geosynthetic Materials Based on Time . Taking the creep test results . To investigate the characteristics of creep and the long-term strength of pre-peak damaged rock under triaxial compression, a series of multi-stage creep tests on .

Compression creep test on expanded polystyrene (EPS) geofoam Y. Z. Beju Civil Engineering Department, Indian Institute of Technology Bombay, Powai, Mumbai400 076, India Correspondence [email protected]

Compression creep tests (CCTs) have been widely used in phenomenological characterization of viscoelastic materials such as glasses. However, disturbed by specimen-tool interface friction, the real stress-strain data regarding the pure viscoelastic deformation are frequently misestimated in conventional CCTs, causing decreased accuracies of the derived . To do so, confined compression creep and recovery tests were conducted on cartilage explants (N = 10), and the resulting mechanical properties from both the creep and recovery phases were compared . 3.4. Uniaxial compression creep test (UCCT) The creep compression test was performed following ASTM Standard C512-02 [38] with the test set-up shown in Figs. 3.The cylindrical samples were loaded to roughly 30% of the f ′ c measured at 28 days (see Table 2).The creep deformation was measured on 2 cylinders for the 4 different conditions considered in .

test specimen as a result of compression, deflection, or exten-sion: 3.1.4 compression—in a compressive creep test, the de-crease in length produced in the gage length of a test specimen. 3.1.5 deflection—in a flexural creep test, the change in mid-span position of a test specimen. 3.1.6 extension—in a tensile creep test, the increase in

Compression and tension creep tests were performed on cylindrical specimens. A compression creep test was implemented by conventional creep testing apparatus with an externally installed load cell to check whether the applied external pressure maintains constant value during the test period. In the tension creep test, a testing apparatus that .

The conventional uniaxial compression test and uniaxial compression creep test were performed using the RMT-301 rock and concrete mechanics testing machine (as shown in Fig. 3). The maximum test force of the equipment is 1500 kN; the accuracy is 0.5%; the deformation rate range is 0.0001 to 1 mm/s; and the loading rate range is 0.01–90 kN/s. This multiple-stage deformation behavior is typical in the compression creep test of polymeric material [50, 51]. It is due to the densification of the fibers, which increases their mechanical . Recently, Zhang et al. [23] found that the creep modulus C u measured by Uniaxial Compression Creep Test (UCCT) over 20 years for many types of cement paste and mortars correlate fairly well with the contact creep modulus C i h o m measured by microindentation techniques at the level of the cement paste and eventually homogenized to the scale .

The following bulk compressive creep test was the same for two groups and repeated for 5 rounds for each hemisphere, in which a 2 N-preload was applied, and then increased to 300 N with a loading rate of 10 N/s. . Among these options, the compression test is closest to the loading state of most oral resin restoratives and cement materials. Creep in compressed gaskets is often mitigated with compression stops, or set compression heights. Compression set is the most commonly tested property for elastomeric gaskets/rubber materials. Test data . Subsequently, the compression test device was implemented by a series of creep tests on various commercially available polyurethane foam grades provided by Getzner Werkstoffe GmbH (A). The chosen materials are .

compression creep test were performed using the RMT-301 rock and concrete mechanics testing machine (as shown in Fig. 3). The maximum test force of the equipment is 1500 kN; the accuracy is 0.5%; the deformation rate range is 0.0001 to 1 . For this reason, a new temperature-controlled triaxial compression and creep test device, operated automatically by a computer-controlled system, whose control software has been developed by the . Expanded polystyrene (EPS) geofoam is vulnerable to time-dependent creep deformation when a constant magnitude stress level is applied. In the present study, an attempt has been made to understand the behavior of compression creep of EPS geofoam using stress controlled loading frames. The test has been carried out on EPS geofoam samples of three .

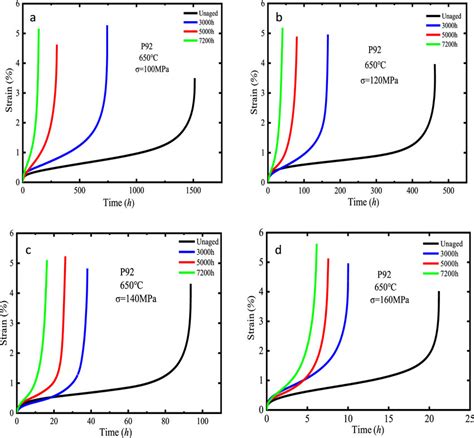

strain versus time creep curve

To evaluate the applicability of short term creep test result for a longer time creep condition, which is of interest in design situations, some long-term (up to 180 days) creep tests were conducted for compression molded virgin and blow molded laminated HDPE at 23 °C.

creep phenomena, a number of assumptions have been devel-oped that have been generally substantiated by test and experience. 3.3.1 Creep is proportional to stress from 0 to 40 % of concrete compressive strength. 3.3.2 Creep has been conclusively shown to be directly proportional to paste content throughout the range of paste Table 1 lists the triaxial mechanical test and creep test schemes for hydrate-bearing samples, where the shear stress level is the percentage of shear stress applied in the creep tests in the strength of the cores. During triaxial loading, the strain rate is controlled at 0.3 mm/min. Creep testing. Of the compression protocols, the least commonly performed is creep testing. Creep evaluation involves the application of a constant load as the sample continues to deform, eventually reaching equilibrium (Fig. 2A, right). Unlike ramp and stress relaxation testing, creep testing is rarely performed in an unconfined configuration.

Conduct the compression creep tests as required by the applicable sections of ASTM E 209-65. 6.2.1.5 Short-Time Tension Creep Tests . Creep test data shall be presented as plots of strain vs times or stress vs time-to-rupture. Because of the length of time required to conduct these tests, few creep tests are rerun and often the tests are not .

The creep test has the objective of precisely measuring the rate at which secondary or steady state creep occurs. Increasing the stress or temperature has the effect of increasing the slope of the line ie the amount of deformation in a given time increases. The results are presented as the amount of strain (deformation), generally expressed as . The strains measured in the creep tests in compression, in direct tension and in four points bending on specimens from the same concrete batch have been plotted in Fig. 8. The results reported correspond to the raw data obtained during the creep test in compression (Fig. 8 a), in direct tension (Fig. 8 b) and in four-point bending (Fig. 8 c . In ceramics a creep test at constant load and temperature is generally performed at prolonged times, because of the bond character in ceramics. . Compression creep curves recorded at 238 MN m −2 and 1623 K for samples of reaction-bonded and hot-pressed silicon nitride, a SiAlON (z = 1) and sintered silicon carbide. The hot-pressed sample .

12a rotary compression test

12mm compression test hose

23 de fev. de 2024 · A Lynx Air Boeing 737 jet sits at a gate at the international airport in Calgary on Feb. 23, 2024. Officials with the Calgary-based company announced .

compression creep test|creep recovery test